Triquetra Tool Box for Arduino/GRBL and Mach3

$20.00

This is a Windows Program. It will run on a Mac that has Windows Emulation enabled.

If you use a OneFinity Touch Plate or the Triquetra Touch Plate with the OneFinity CNC machine, please use the OneFinity Companion instead of this product.

Click here to view the product installation guide and other FAQ’s before you order this product.

If you are a current Triquetra Touch Plate Owner or a G-Code Generator Spreadsheet owner, click Here to request an discount code for even more savings prior to placing your order.

This is a download of the Triquetra Tool Box and is an upgrade from the G-Code Generator Spreadsheet. Touch Plate NOT included. It is for use with Windows XP thru Windows 10 only and does not require Excel to use.

Software downloads are non-refundable so please read the Product Compatibility and Description below before ordering.

Description

-

This product is available in High Resolution and Low Resolution to increase compatibility with various computer monitors. Both are available for download with this purchase. You can access them from the My Account page at any time.

-

Compatibility: This is a Windows based application and does not require Excel to use. It is compatible with Windows-XP thru Windows-11

-

The only difference in the two versions is the support for screen sizes. There is a version for High Resolution Monitors that are typically wide screen (16X9) and one for Low Resolution Monitors that are not wide screen (4X3). Both versions are included in your purchase and available for download.

-

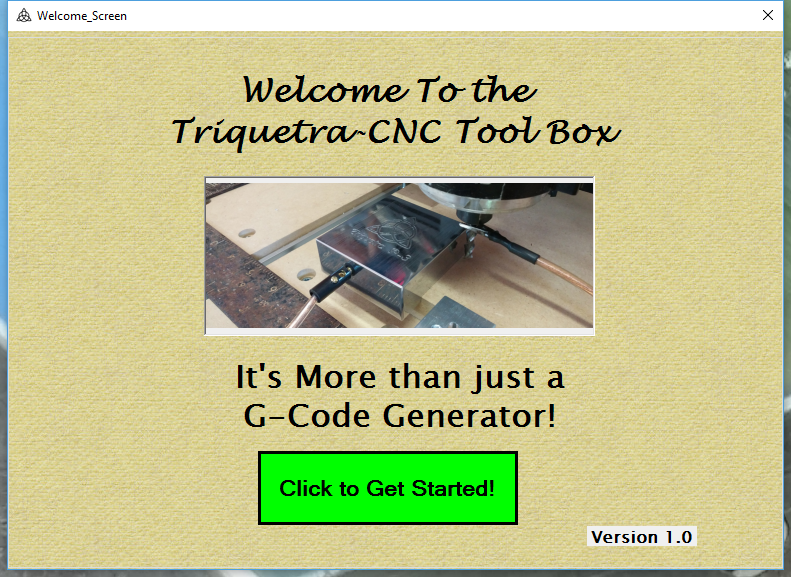

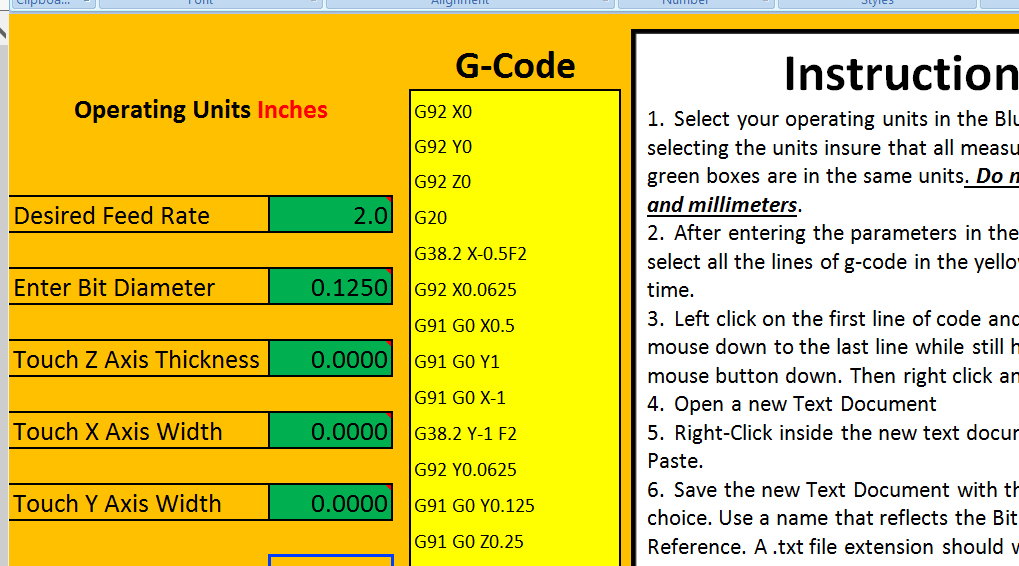

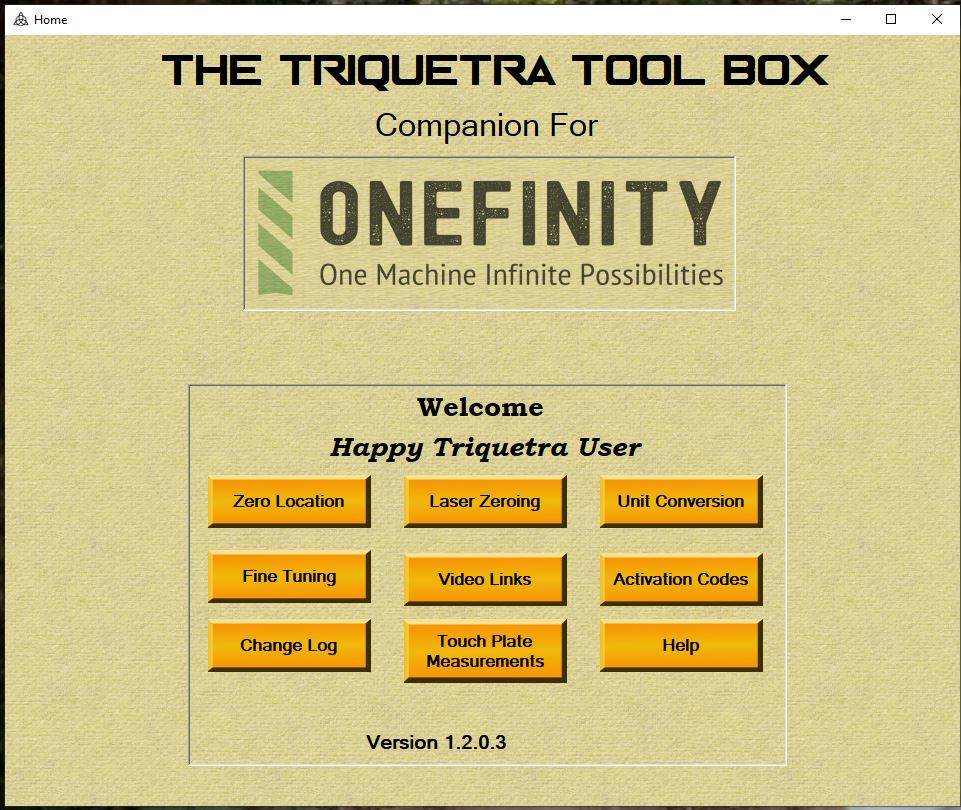

The all new Triquetra Tool Box is much more than just a G-Code generator for automatic 3 axis zeroing. This new application greatly simplifies creating zeroing g-code for automatically zeroing X, Y, & Z axis as well as the Z axis only. It does not require you to copy and paste code to a file. It automatically generates the code, creates the file, and saves it in a folder location and file name that you have complete control over. You can now create standard g-code files to set your origin at the left front corner, right front corner, material center, or any other offset you like.

-

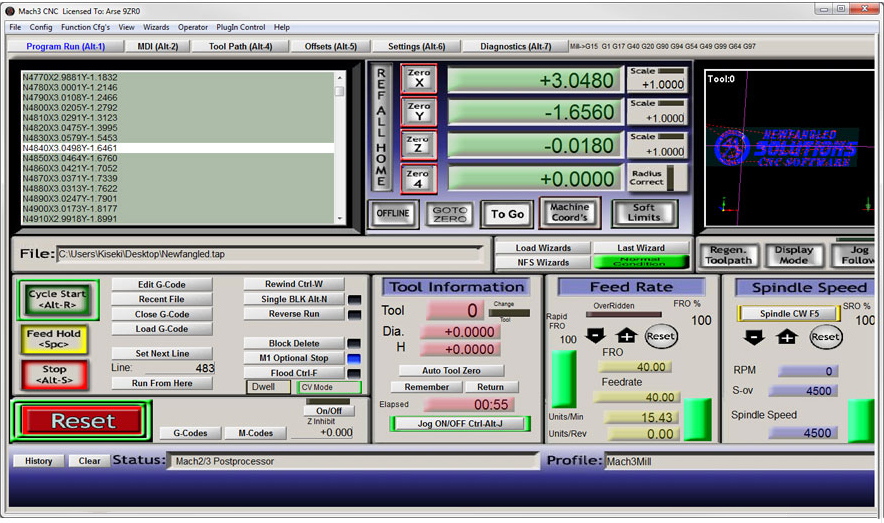

Mach3 and UC-CNC script generation are also included. You can create either script that runs in Imperial units (Inches) or Metric Units (Millimeters). The functionality to zero all three axis at one time or just the z axis is built in to the script.

The Triquetra Tool Box has the following additional Features:

-

Unit Conversion Page: This page is one of the most popular among the Beta Testers. It easily converts Inches to Millimeters, Millimeters to Inches, and Fractions to Decimals. A very handy tool indeed.

-

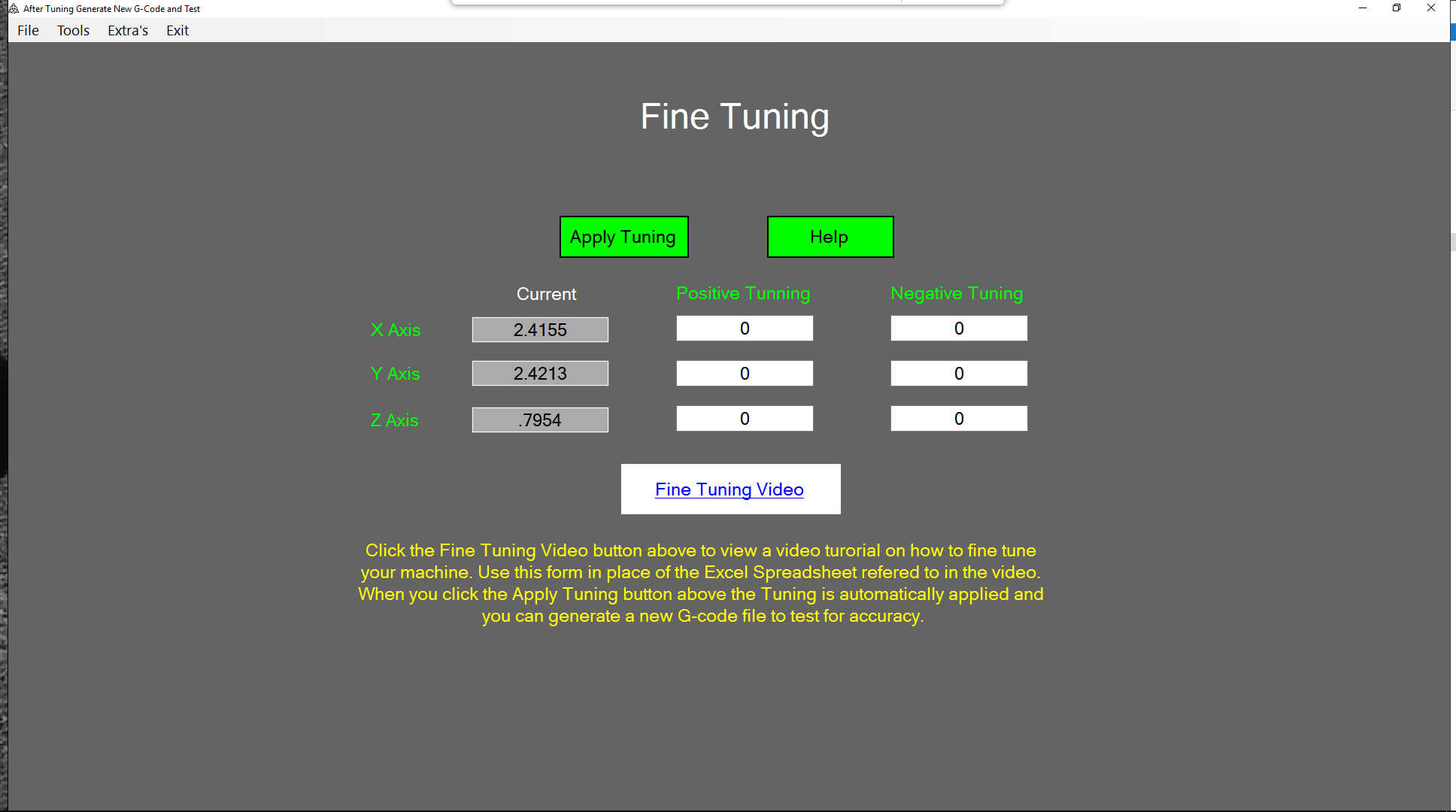

Fine Tuning Page: This page simplifies fine tuning of your g-code file. There is a link on the page to a video tutorial that will guide you. This is a process that greatly improves the accuracy of your 3 axis touch plate. It is automatically applies the changes for you to insure the corrections are applied in just the right places to generate zeroing g-code that will be consistent and accurate.

-

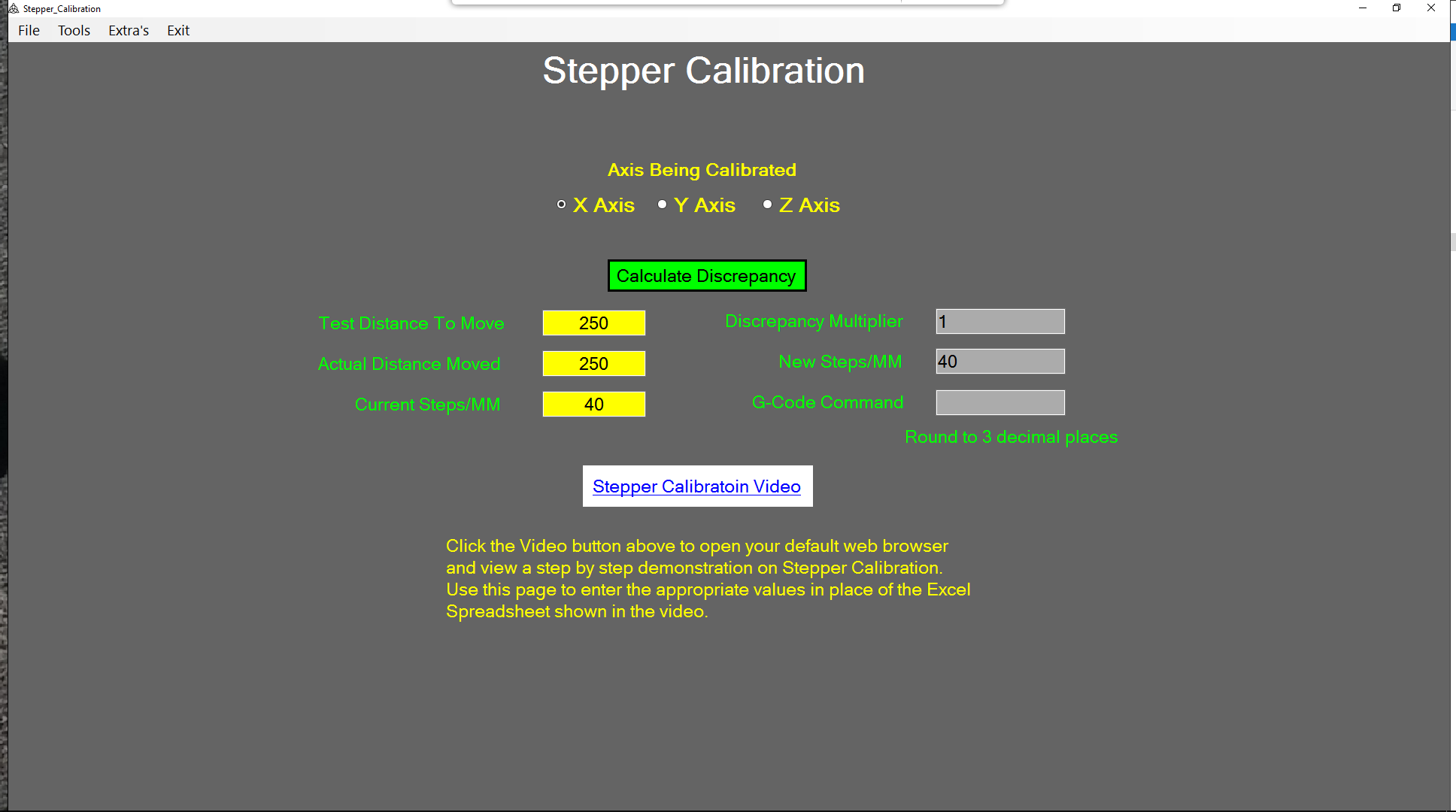

Stepper Calibration Page: The key to creating accurate carvings is to have accurately calibrated stepper motors. This page calculates the corrections needed and displays the code to apply the changes. There is also a link to the step by step video guide on the page with detailed instructions.

-

Customer Orders Page: You can toss out the paper notebook. Now you can enter all the data on this page to keep track of your own customer orders. You can enter tracking numbers and track the location of your shipments with a tracking link directly from this page. There are numerous database fields for entering everything from Customer information to parts and pricing.

-

Recipe Page: All of us struggle to figure out just the right settings to use for a particular project. We tweak the Feed Rate, Depth of Cut Step Over, Bit Sizes and Types, Material Types, and so on. All in an effort to duplicate that perfect carving. What we lack is a way to save that information once we hit the sweet spot. With the Recipe Page, you can enter all of the applicable data and save it so that you can refer back to it at a later date when you want to use that same bit with the same material again. Or perhaps you are going to duplicate that project. No more lost pieces of paper, or paper that got ruined by spilled coffee. Just go the Recipe Page and sort the list by any of the headings to find what you used before that worked!

-

Parts Book: How many times have you ordered a new bit and loved it. Then you needed to re-order it and couldn’t remember where you got it from. What about the guy in the forum that is looking for a resource for a particular part that you told him about? Now you don’t have to search through endless web sites or stacks of papers in a drawer to find it. It’s in the parts book and easy to find.

![]()

![]()

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.